There was once a pianist who poured his heart and soul into recording in the studio, believing that the vitality of music lay in the art of recording. On the other hand, a conductor firmly believed that the true life of music could only be experienced in live performances. The pianist left behind a treasured recording, while the conductor left behind valuable live broadcast recordings. The musicians deeply considered the meaning of each note and symbol, filling them with the internal meaning of music. Even in live performances, once the music began, the music creators were the only ones present. If one note was overlooked, it would inevitably become a weakness.

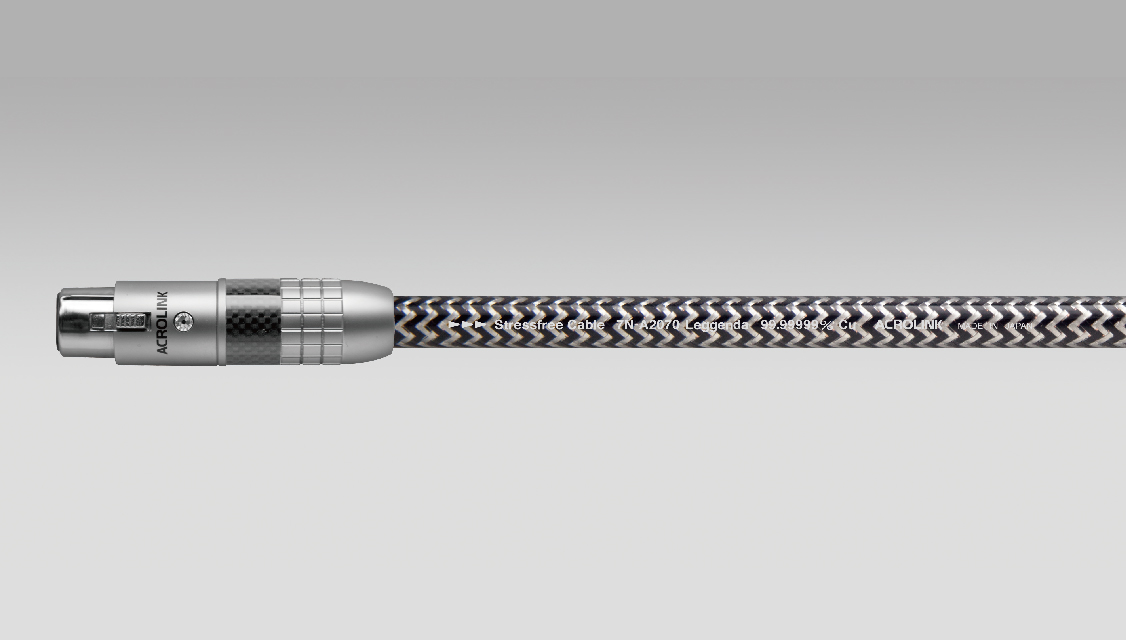

The same is true for the development of audio cables. If one material compromises, the true "music" connection cannot be expected. Japan's material manufacturing technology is constantly evolving. Acrolink can accurately grasp and reflect this evolution, without any hesitation in implementation. It uses ultra-high purity copper with a revolutionary large grain and directional properties, with a true purity of 99.99999% and Acrolink's unique impeccable processing. The conductor uses Acrolink's supreme balance = 19 single wires with a diameter of 0.26φ, evenly coated with Squaran oil and twisted in reverse at high density and optimal tension. The hot side uses natural color polyethylene without additives, and the cold side uses polymer polyolefin (black) for coverage. By using the interaction of different materials to produce a synergistic effect, the sound quality is further improved. Between these two conductors, silk thread and electromagnetic wave absorbing non-magnetic wire are arranged to enhance static electricity removal, and an internal sheath made of a mixture of tungsten and amorphous powder mixed with polymer polyolefin is used to suppress unnecessary vibration. In addition, a double-layer shielding layer composed of copper foil tape and UEW+silver-plated soft copper wire braid is formed on the outside, and a UV-resistant transparent polyurethane material is used for decoration. Of course, the material structure of the connector is also unique to Acrolink. The RCA plug uses the inheritance of 7N-A2070II. The center pin uses beryllium copper 50. After mirror silver plating and the highest-grade thick film ruthenium plating, it is covered with natural color polyethylene. In addition, the nut between the connector and the plug uses pure aluminum with excellent vibration reduction properties. It is an ideal RCA plug that is more efficient.

For XLR plugs, Acrolink uses the highest level model in its original connector, which also uses the 8N-A2080 Performante plug. It uses high-quality diameter sound quality cobalt copper (male) and beryllium copper (female), which are treated with high-grade direct silver plating. Its plug body is made of pure brass material and combined with carbon fiber, becoming Acrolink's unique high-precision high-quality connector, which is very sturdy. Acrolink's exploration has exceeded a quarter of a century, and thorough material selection, design structure, and original connector design are all "refinements" that only time can bring. Even though they are called the same item, improvements such as purity, hardness, and durability, updated materials that are more suitable for audio cables, have achieved superior audio transmission capabilities and spatial information transmission characteristics than ever before. This is the birth of Acrolink's latest work, the 7N-A2070 Leggenda.

Welcome to leave your comments for other users' reference