Every audiophile has their own milestones, and in fact, the 2-core shielded cable "A2110" has become one of the world reference standards. After robust development, it has now entered the fourth generation "Leggenda" stage. The fact that signals pass through the conductor is indisputable, and the pursuit of excellent quality is always the top priority.

99.99999% = 7N. Through Acrolink's unique impeccable self-recovery Streefree stress handling, for example, during wiring bends, long-term purity and crystal structure have been achieved. In addition to the high-quality knowledge accumulated since the 6N era, Acrolink has also invested more resources to carefully craft "equally usable" wires of higher levels, which can provide more value even when upgrading audio equipment. This is the beginning of high-end audio. As the system develops and scales up, it is inevitable that there will be cross-interference, contact between wires, and mixing of analog and digital devices, and various kinds of noise will occur in unexpected ways and levels. This situation starts from simple levels. Acrolink foresaw this "inevitability" before other companies and thus took multiple measures from various angles from the beginning, such as introducing noise suppression bands that do not require magnetic cores. Standing on the coordinates of transmitting pure signals. This is Acrolink today.

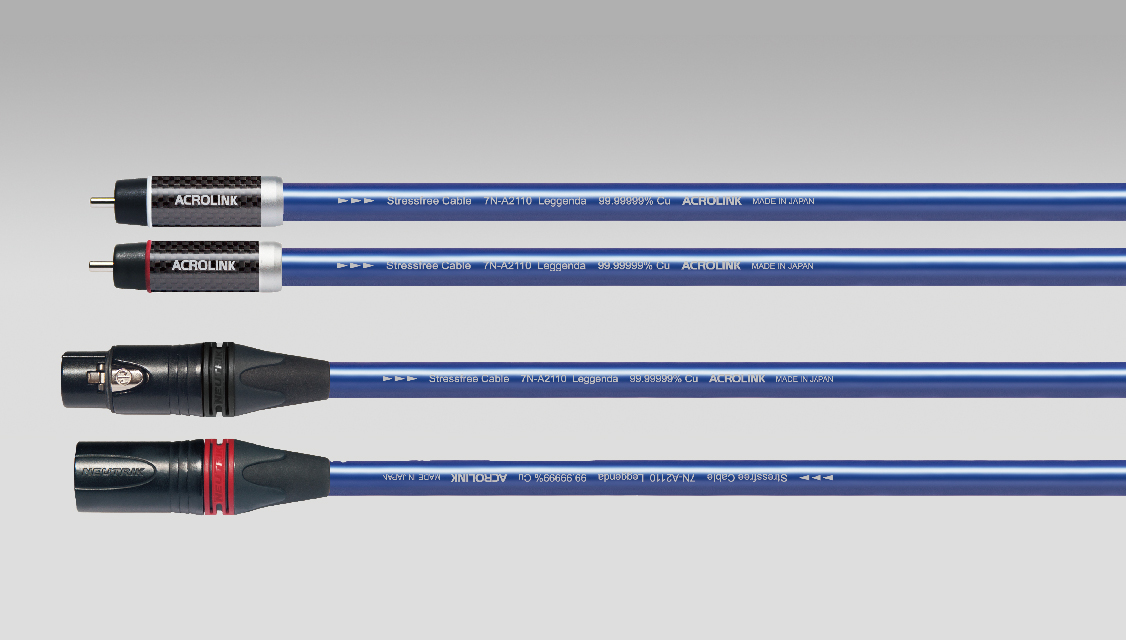

The naked copper wire D.U.C.C. Stressfree 7N Cu, with a diameter of 0.18mm × 34 strands, is coated with insulation layers of polyethylene (hot = white) and polyolefin (cold = black) to form a core wire with a diameter of 2.2mm. Then it is fixed with a soft polyolefin inner sheath. Copper foil strips and 4N5-OFC cross-winding form a double-layer shield to prevent external noise interference. Then it is wrapped with paper tape to reduce the static level and achieve the original performance and sound quality of the 2-core shielded cable = high-speed broadband and high dynamic sound. At the same time, the RCA plug uses Acrolink's new original component. It adopts an aluminum and carbon fiber composite structure with different vibration modes and a heavy design, which greatly reduces unnecessary vibration. The center pin uses tungsten copper with excellent transmission characteristics, and adopts a hollow tube structure and direct rhodium plating to further improve transmission performance. In addition, a protective sleeve is introduced for the first time at the cold end. For XLR connectors, Acrolink uses products manufactured by the unwavering Noitric company, which are very reliable in practice and reputation. The contact ends of the male and female sockets are made of high-quality brass without bottom layers and are directly gold-plated. The die-cast zinc shell has a large meat thickness and super heavyweight, which can suppress unnecessary vibration and help reduce micro-vibration noise. In conjunction with the cable itself, it can achieve low distortion and extended frequency response range to more than ten GHz in the auditory range to achieve essential sound quality improvement.

Welcome to leave your comments for other users' reference