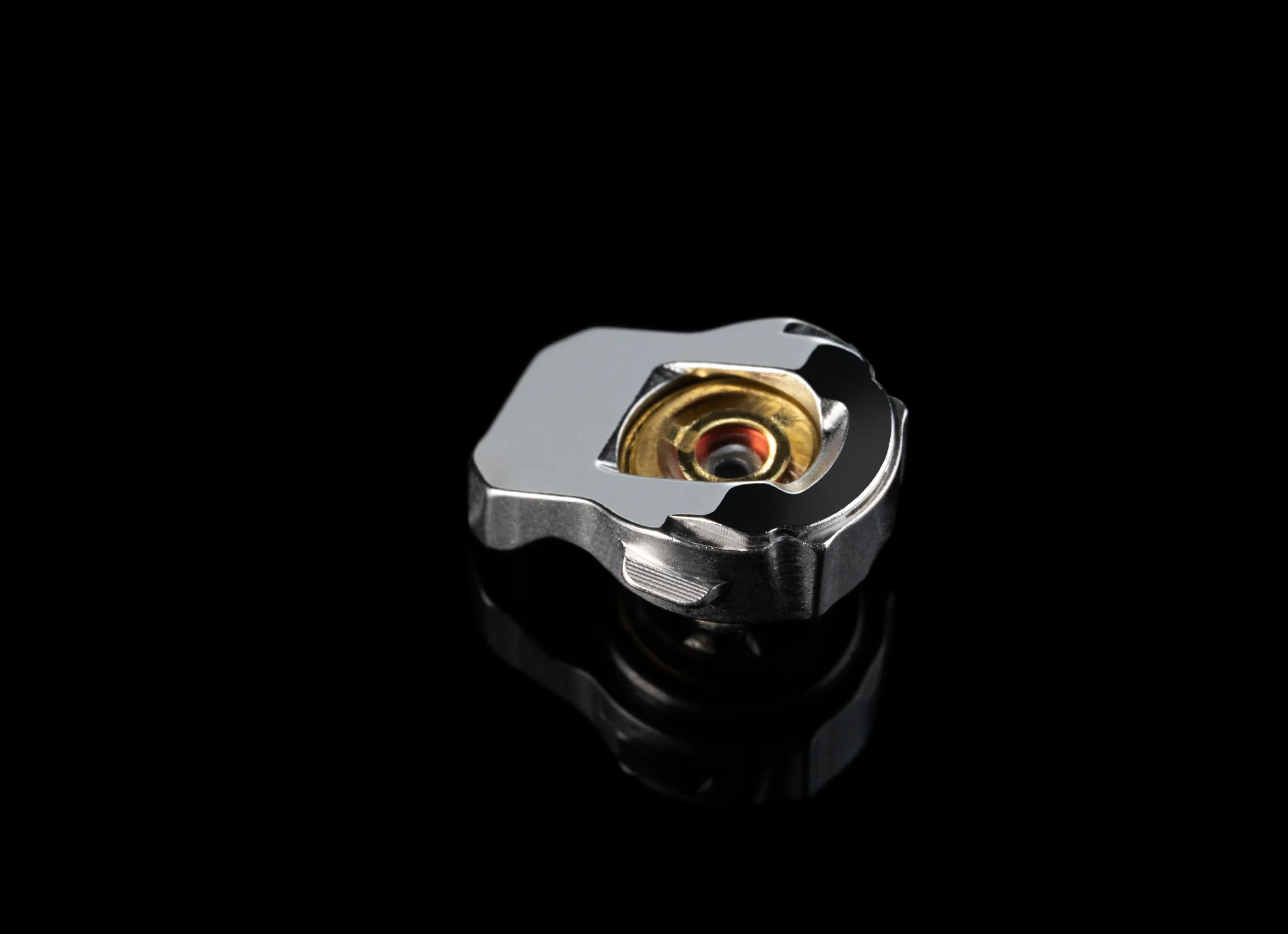

As a series focused on sound quality, the A series holds extremely high standards for unit performance. Therefore, the new stainless steel-encased brass unit is built on the foundation of the proprietary f-Core DU dynamic driver.

This unit, including the diaphragm, voice coil, magnet, magnetic circuit, adhesive components, and production equipment, is entirely produced in-house by Final, ensuring quality control. Particularly, to achieve a smooth and uniform diaphragm surface for higher sound fidelity, the brand spends three times the usual production time, preventing production errors due to overworking the machinery, thus enhancing diaphragm precision and quality.

In addition to the high-precision diaphragm, the f-Core DU dynamic driver’s interior features a voice coil made of 30μ ultra-fine copper-clad aluminum wire (CCAW) to ensure lightweight performance. Minimal adhesive is used during assembly to bond the diaphragm edges to the unit housing, ensuring that the diaphragm operates without causing the entire unit to vibrate, which could affect performance. The unit’s front chamber is made of brass, providing rich and bright sound characteristics.

To further enhance unit stability and achieve higher sound fidelity, the brand has incorporated a CNC stainless steel mount, mimicking the flagship A8000’s design of directly mounting the unit in a stainless steel housing. This not only improves resonance suppression but also brings the sound emission point closer to the nozzle for more efficient transmission performance.

With the combination of the diaphragm, f-Core DU, and stainless steel unit mount, the A6000 achieves efficient detail reproduction and precise sound positioning while maintaining a certain level of warmth, offering superior sound performance.

final is meticulous about headphone design to enhance wearing comfort and stability. Since the B series, Final has adopted a “three-point support design” on the headphone housing. This design evenly distributes pressure points across the ear canal, earlobe, and concha, further dispersing excess resonance.

To enhance sound transmission performance, the brand equips the A6000 with its proprietary Type-E For TWS ear tips. These short ear tips provide a higher degree of fit, and the large-diameter nozzle enhances high-frequency extension and spatial performance, further optimizing performance.

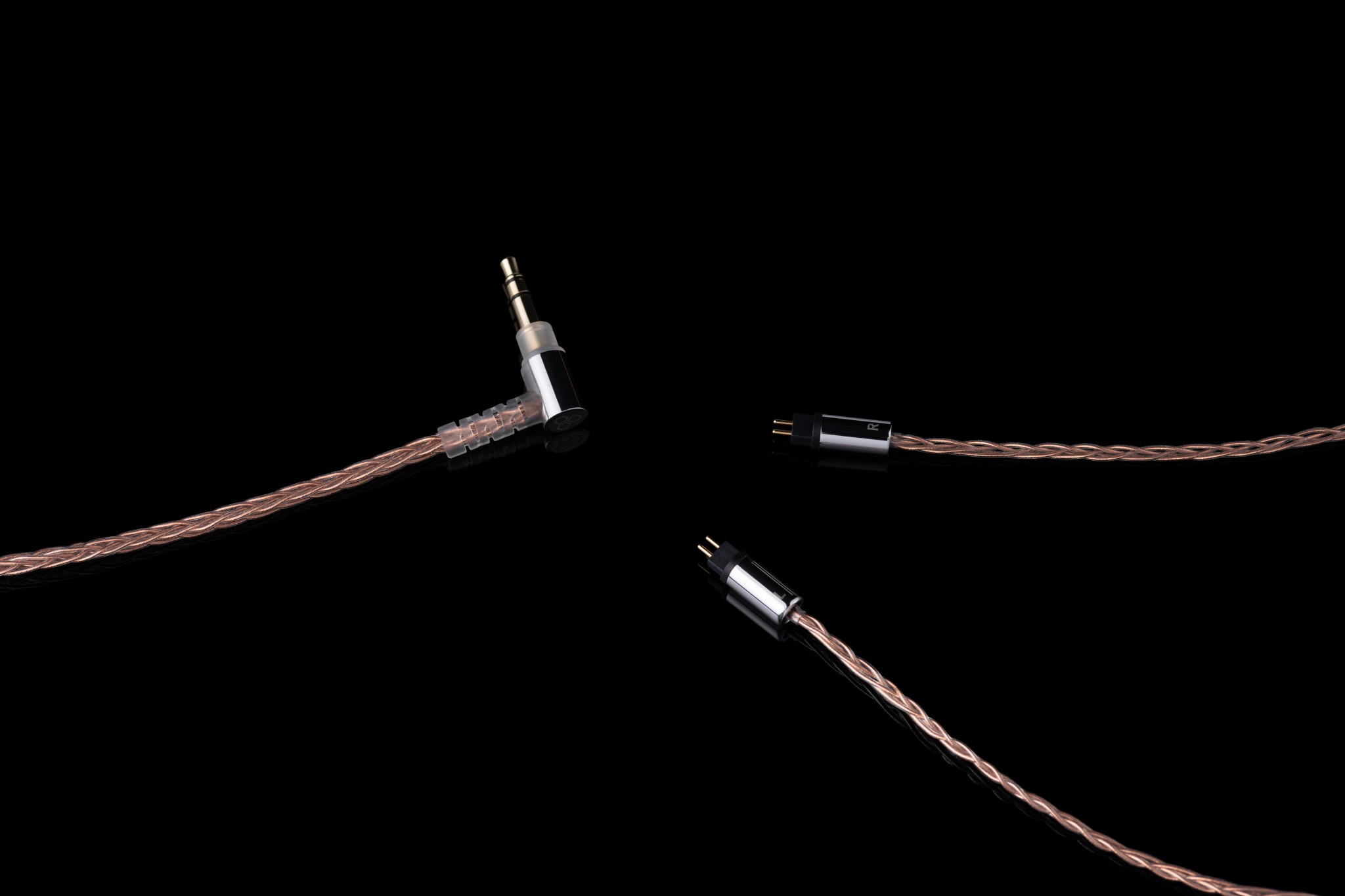

Unlike the previous A series cable configurations, Final has developed its own single-crystal copper cable for the A6000. This cable aims to enhance current transmission performance and fidelity through the high conductivity and dense internal structure of single-crystal copper, achieving a uniquely transparent sound performance in conjunction with the f-Core DU.

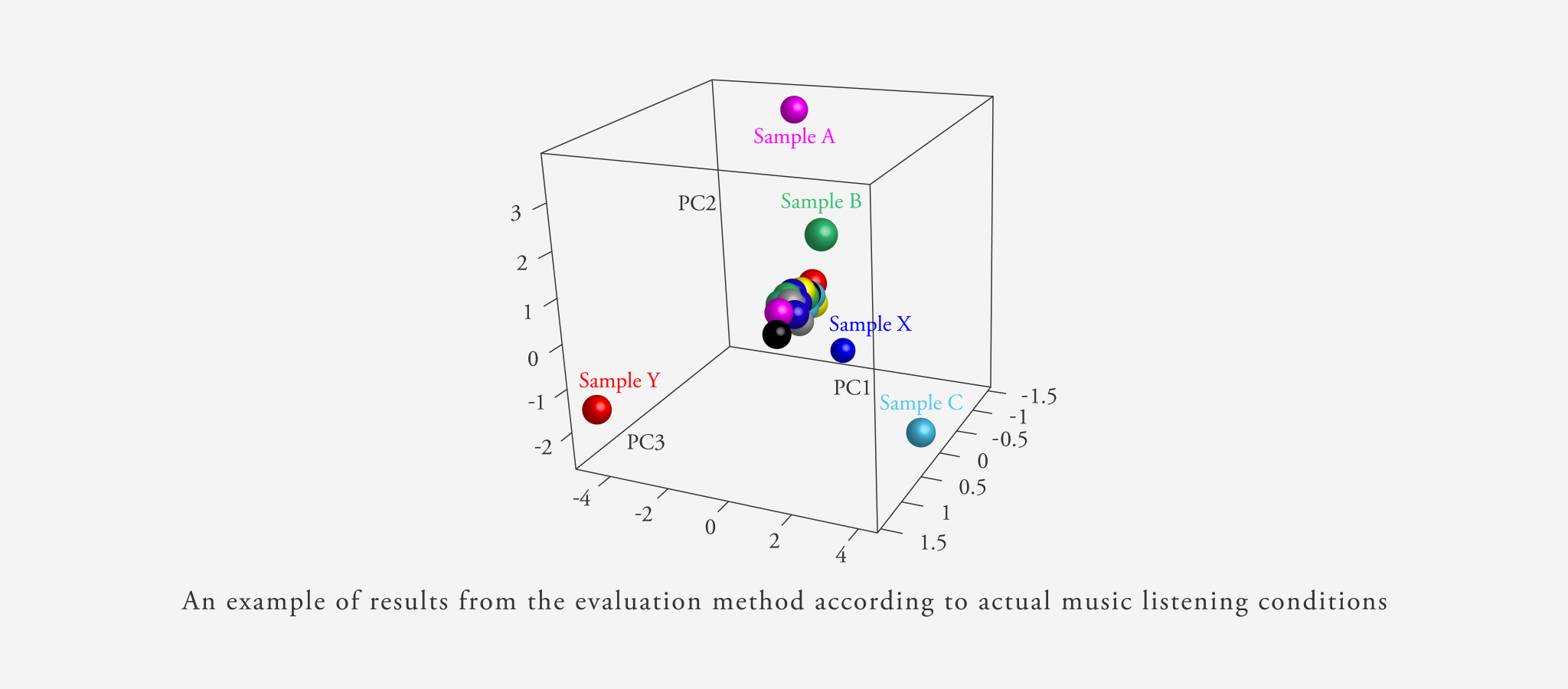

Besides the headphone unit, various subjective elements such as physiology, emotions, and cognition affect the user’s listening experience. To combine the objectivity of unit design and cables with subjective elements like emotions and cognition, the brand has developed its own evaluation method, “PTM” (Perceptual Transparency Measurement). By analyzing different individuals’ sensitivity to sound, the A series is designed to produce the most “transparent” sound. The A6000 also applies this method in tuning, resulting in superior spatial and detail positioning performance.

Product Specification

Driver

Stainless Steel-Encased Brass Unit

Sensitivity

100dB/mw

Shell Material

ABS

Impedance

18Ω

Cable

8 Wired OCC

Cord length

1.2m

Weight

24g

Welcome to leave your comments for other users' reference