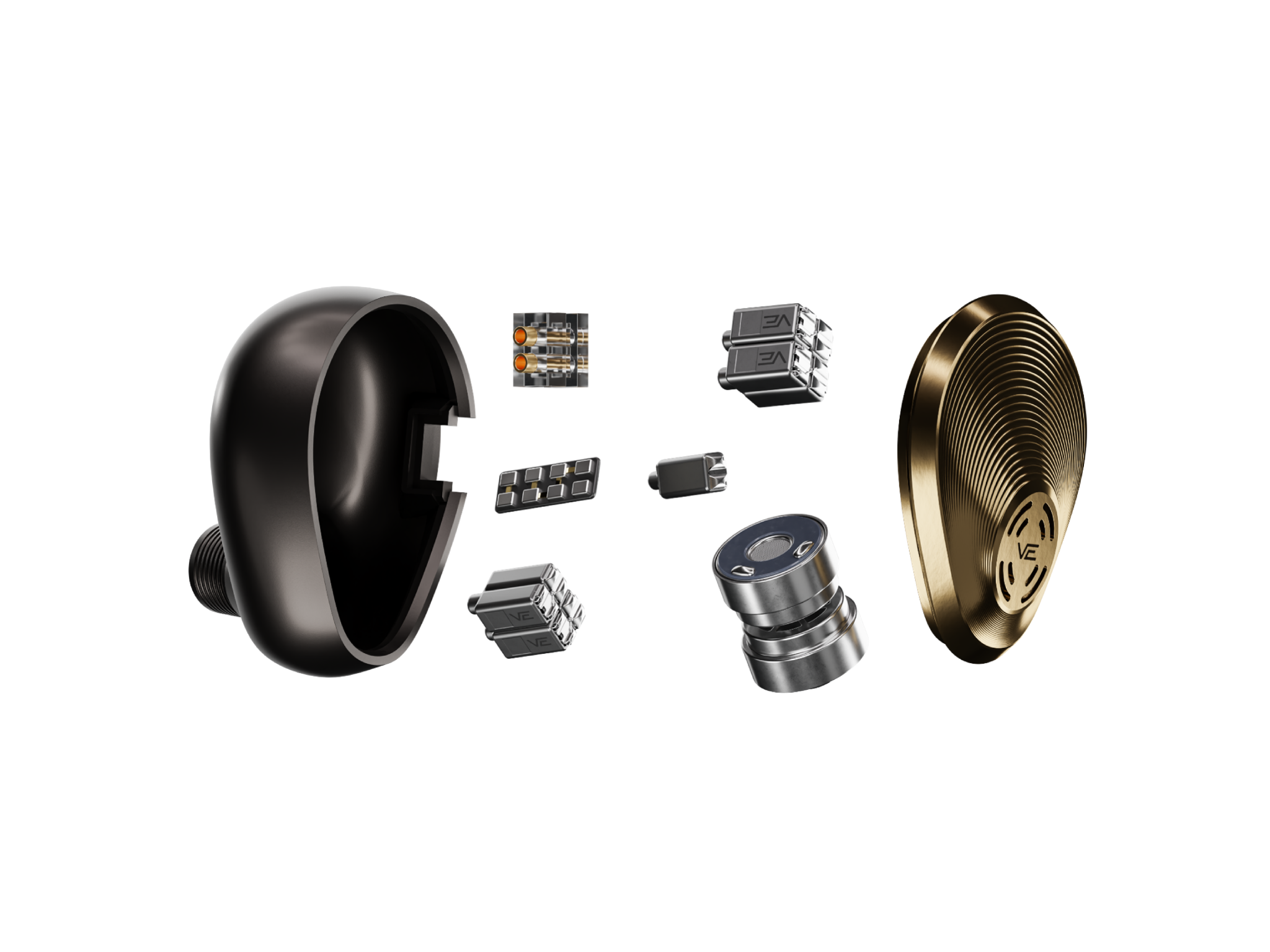

As Vision Ears' first circular iron hybrid headphone, AURA partners with Astell&Kern with an uncompromising spirit and each company's proprietary technology. AURA utilizes the most advanced techniques and carefully crafted drivers' materials and layouts, allowing the 9BA and 2DD to adopt circular iron hybrid structure to blend together, achieving an overwhelming sound imaging effect. Paired with five-way crossover technology, through precise circuit board routing design, it avoids high-frequency distortion problems caused by overloading of the super high-frequency BA, accurately transmitting sound signals to the units of each frequency band, providing perfect triple frequency response and balance.

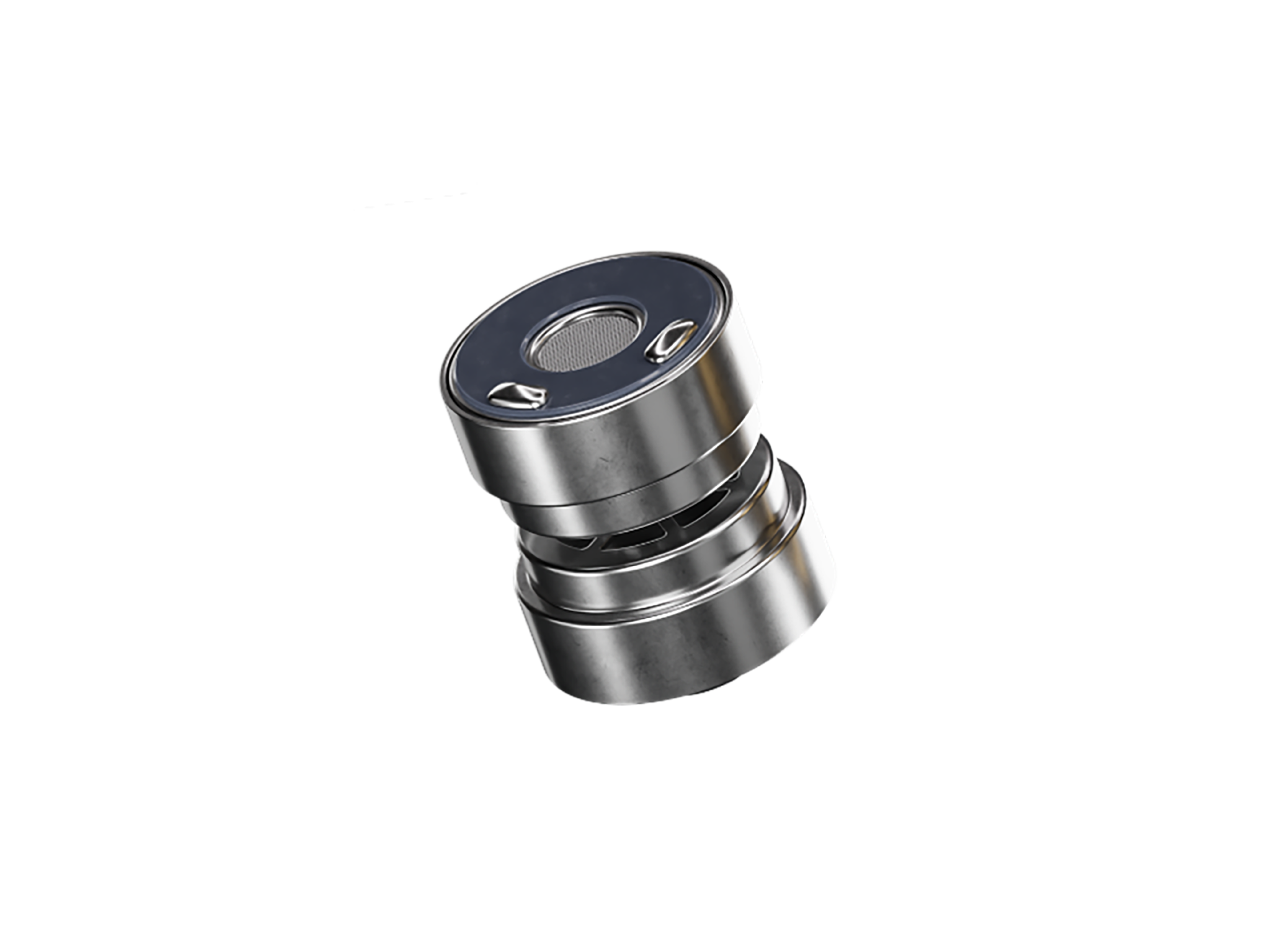

The two 8mm aluminum-magnesium alloy dynamic drivers responsible for the low-frequency part have high rigidity, durability and lightweight characteristics. This allows the moving coil units to quickly return to a stationary state during vibration, reducing unnecessary resonance and improving low-frequency clarity and layered feel. It maintains good linear response in the process of converting electrical energy into sound energy, which also means it can more accurately recreate details in recordings, shaping the low frequencies in a smoother, more natural way.

In considering the layout of the drivers' placement, the design team took into account factors such as the internal chamber space, equivalent volume of the drivers and characteristics of the diaphragm material on low-frequency response. Therefore, an isobaric design was specially adopted, placing the two moving coil units facing each other. When the two moving coil units sound simultaneously, the sound is transmitted outside through ducts over the shortest distance between the units. The goal is to reduce the total harmonic distortion (THD) of the low frequency and eliminate phase problems that may be caused by duct length differences, giving the moving coil units a solid and full low end while maintaining a clean, clear low-frequency imaging.

Due to AURA's integrated metal body, the manufacturer also carried out detailed precise calculations and research on the internal volume of the headphones. A special chamber design was used to balance the transmission speed of the units and musicality, allowing the two moving coil units to match each other, greatly reducing the discontinuous problems caused by phase deviation.

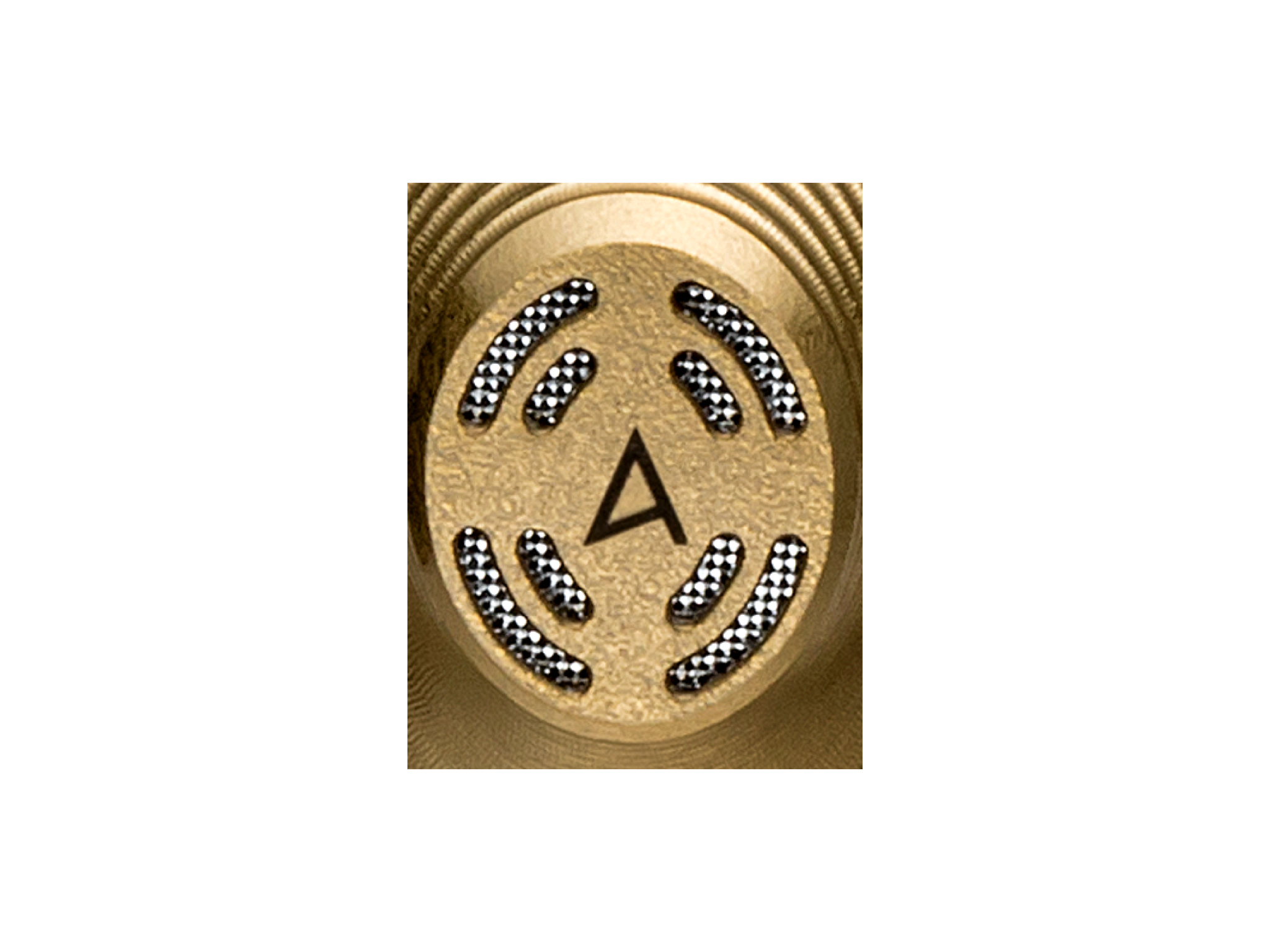

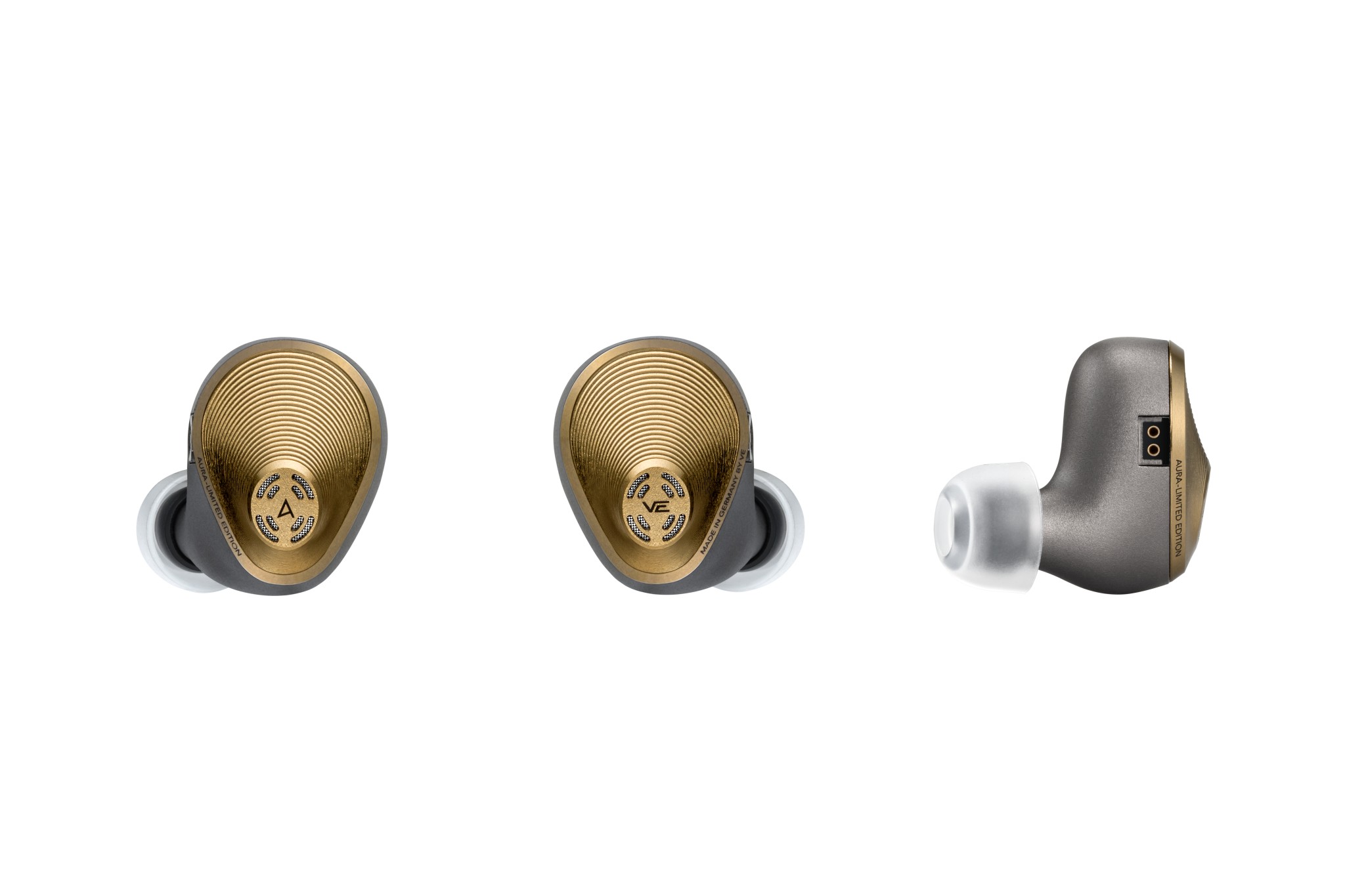

In order to highlight the ergonomic and acoustic advantages of the open-back structure while maintaining AURA's elegant and exquisite exterior design, in addition to laser engraving each brand's logo on the top panel, a vacuum metal mesh design was also crafted in collaboration, continuing the design of the curved microgrooves and gratings to minimize the impact of aerodynamics and air pressure on internal components. This allows the moving coil units themselves to perform at their full potential, creating a vast soundfield and restoring sound to its purest, most natural form.

AURA uses Swiss 6061-T6 aluminum alloy for both the panels and outer shell material. Unlike ordinary aluminum metals, 6061 aluminum alloy has superior ductility and toughness, widely used in aerospace equipment or precision electronic instruments. During the entire aluminum alloy smelting process, casting defects such as shrinkage pores, sand eyes, and gas inclusions are easy to occur. When subjected to T6 heat treatment, it can eliminate gas pores on the aluminum alloy surface layer, making it not only light and solid, but also greatly enhancing the metal strength and corrosion resistance of the aluminum alloy, improving the stability of the metal structure, thereby reducing sound resonance to achieve low distortion. Combined with its high rigidity characteristics, it provides clear and accurate sound details.

Each outer shell requires thousands of hours of craftsmanship to produce through multiple complex processes by artisans. The raw material undergoes independent oil sealing treatment, and then the outer shell surface undergoes special sandblasting and polishing treatment by hand to fine-tune it. Through the anodic oxidation process, an oxide film is formed on the surface. Finally, a warm gray customized coating from Vision Ears is added, piecing together an exquisitely crafted art piece as lustrous as a jewel, giving the outer shell a smooth, mirror-like satin feel.

The design team also ingeniously applied a unique arcuate microgroove design to the panel through milling techniques to create a "Micro Groove Design" surface effect. Each layer of grooves is intricately laser engraved and presents a striking bronze color through oil immersion treatment. Depending on the angle of view, it can present different light and dark surface reflections, with a strong three-dimensional sense and visual impact. It fully conveys Astell&Kern's long-emphasized design philosophy of "unity of light and shadow", while also experiencing Vision Ears' exquisite craftsmanship.

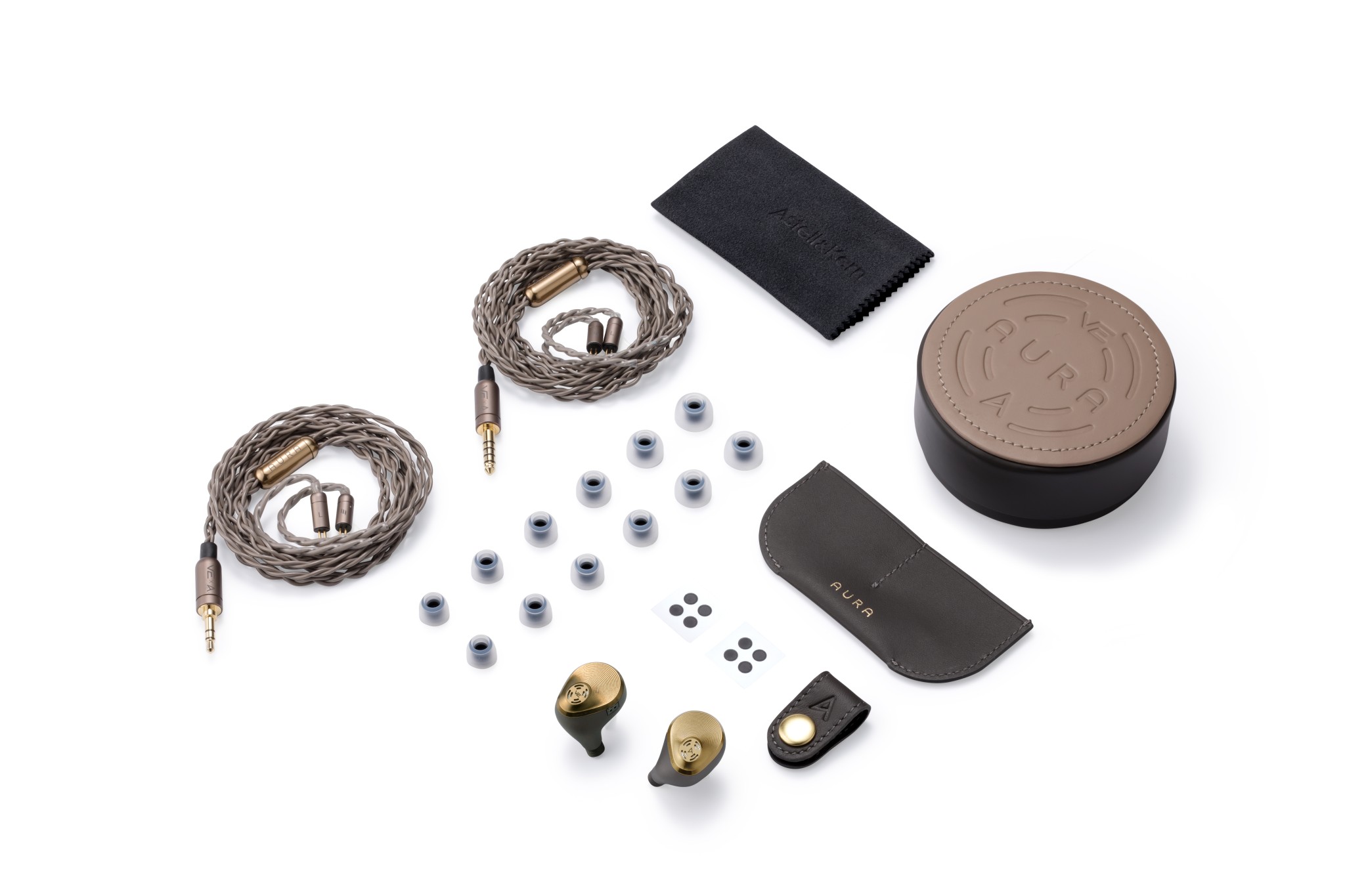

AURA comes with two pairs of Effect Audio custom exclusive headphone cables, including a 3.5mm single-ended plug and a 4.4mm balanced plug. The cables adopt a four-core UPOCC single crystal copper + copper silver mixed braided cable, woven from two UP-OCC pure copper Litz conductors and two copper silver Litz mixed braided conductors, bringing extraordinary sound details to the headphones. Combined with Effect Audio's patented ergonomic optimization technology (EPO), it provides excellent flexibility and elasticity to deliver a more comfortable wearing experience without compromising sound quality.

AURA also includes a leather carrying case set, including a portable bag, headphone storage box and cable clip, all made of premium calfskin specially manufactured by European leather factories, providing soft and delicate textures as well as excellent durability, highlighting its nobleness and grace. For earpads, AURA is equipped with AZLA SE1500 earpads for a comfortable fit that contours closely to the inner ear canal for more refined sound.

Astell&Kern x Vision Ears AURA

Shell

Swiss 6061 aluminum alloy

Spout

Swiss 6061 aluminum alloy

Drivers

Balanced Armature Super Tweeter x1 (High & Super High)

Four Balanced Armature Drivers Set x2 (Mid-low, Mid & Mid-high)

8 mm Al-Mg Low Dynamic Drivers x2 (Sub-low & Low)

Frequency Response

10Hz–24 kHz

Sensitiveness

115dB @ 1kHz, 1mW

Impedance

10.5Ω @ 1kHz

Total Harmonic Distortion

≥0.5%@1kHz

Welcome to leave your comments for other users' reference