At the heart of the DX6000 lies a radical reimagining of dynamic driver design. The diaphragm is crafted from a high-rigidity magnesium alloy, with the dome surface undergoing an advanced oxidation treatment. Subtle yet critical design enhancements—such as folded-edge detailing—strike an optimal balance between stiffness, bending resistance, and long-term durability. These refinements significantly suppress modal breakup and unwanted resonance, ensuring the most accurate transmission of sound.

In a bold departure from conventional materials like rubber or plastic, the DX6000’s surround is constructed from a molded silicone-infused foam—formed as a seamless, unified structure. This innovative material functions like a shock-absorbing foundation for the driver. Lightweight, soft, yet structurally dense, it resolves the long-standing conflict between diaphragm agility and resonance suppression.

This manufacturing technique took final several years to perfect. The process involves placing the magnesium diaphragm into a precision mold and injecting the silicone foam directly, eliminating the inconsistencies often caused by traditional adhesive bonding methods. The result: a level of structural integrity and acoustic consistency that sets a new standard in dynamic driver technology.

A common issue in dynamic driver construction lies in the voice coil lead wires. Traditionally, these wires are glued to the diaphragm surround to prevent breakage—but this attachment often disrupts the symmetry of diaphragm movement, introducing distortion and limiting precision.

To achieve true pistonic motion, final adopts an innovative approach: the Air-Wired “Floating Lead” system. Instead of bonding the wires to the surround, the lead wires are suspended independently, allowing the diaphragm to move freely and naturally without mechanical interference.

To ensure both mechanical reliability and optimal conductivity, final utilizes its proprietary aluminum alloy wire, developed in-house. This exclusive lead wire material is not only lightweight and durable but also acoustically transparent.

By combining floating lead architecture with meticulous material engineering, final effectively eliminates distortion, reverse resonance, and other artifacts that commonly plague traditional designs. The result is an ultra-fast transient response, a distinctive low-end character, and a remarkably open and uncolored soundstage—hallmarks of the flagship DX6000.

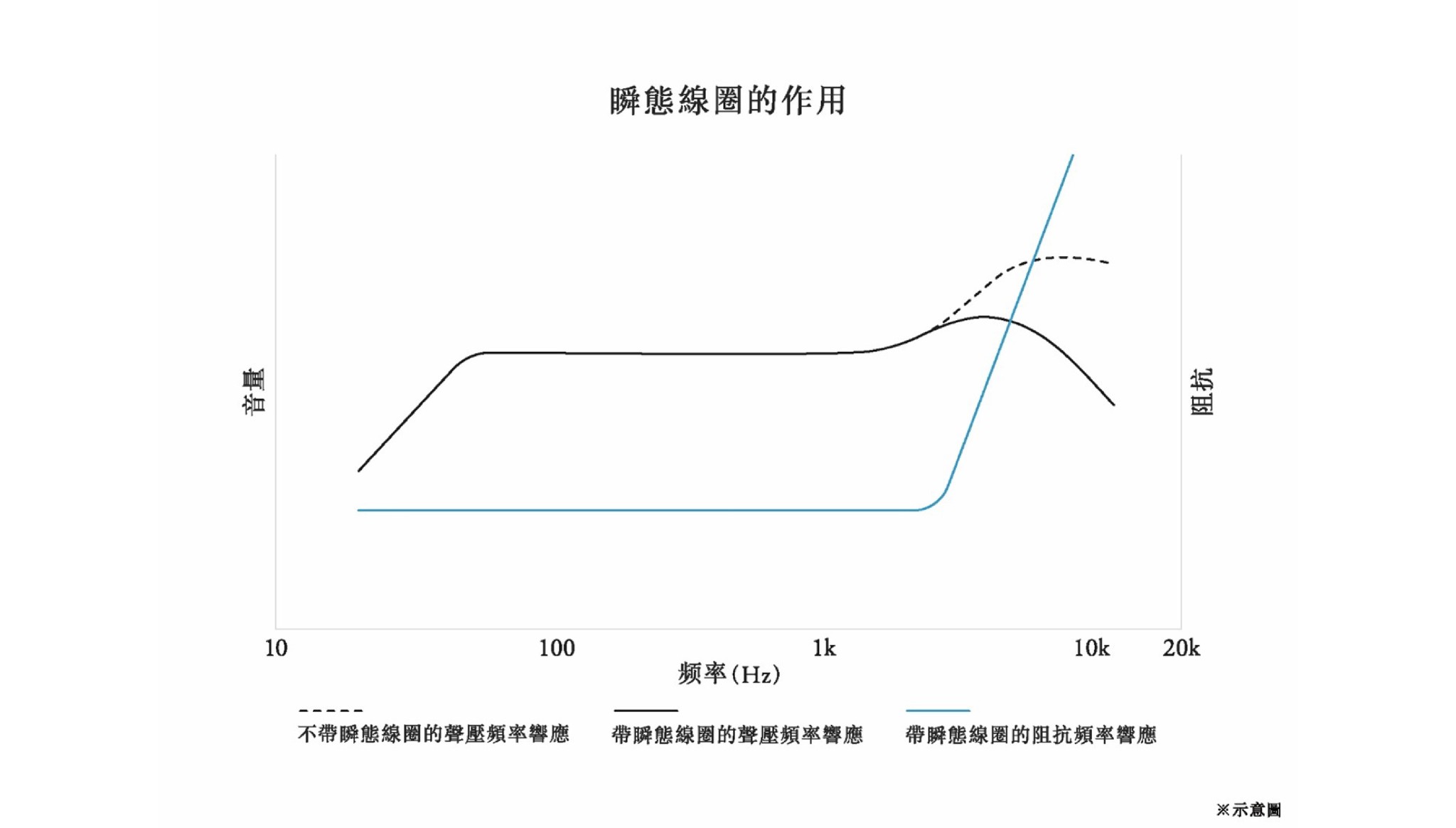

To improve signal responsiveness and maintain high-fidelity audio reproduction, the DX6000 incorporates a newly developed circuit architecture: the Transient Coil System—a pioneering innovation in the headphone world.

In conventional open-back headphones, excessive high-frequency rise is often mitigated by increasing the number of voice coil windings, thereby raising impedance and inductance (L). While effective at softening treble peaks, this approach adds mass to the diaphragm assembly, degrading both transient response and pistonic accuracy. When combined with soft surround materials—used to lower the diaphragm’s resonant frequency (f₀)—the result can be sluggish, imprecise motion and smeared detail.

final’s Transient Coil System solves this dilemma with a first-of-its-kind series coil configuration, acting as a smart, frequency-sensitive damping valve. This system dynamically adjusts impedance across the frequency spectrum without adding mass to the diaphragm. At the standard reference frequency of 1 kHz, the impedance is maintained at 47Ω, but at 20 kHz, it rises sharply to 480Ω.

This deliberate impedance shaping prevents high-frequency overshoot, preserving tonal balance and smoothness. More importantly, it allows the diaphragm to retain its ultra-lightweight design, ensuring lightning-fast transient response and uncompromised control—resulting in razor-sharp articulation and deep, tightly textured bass.

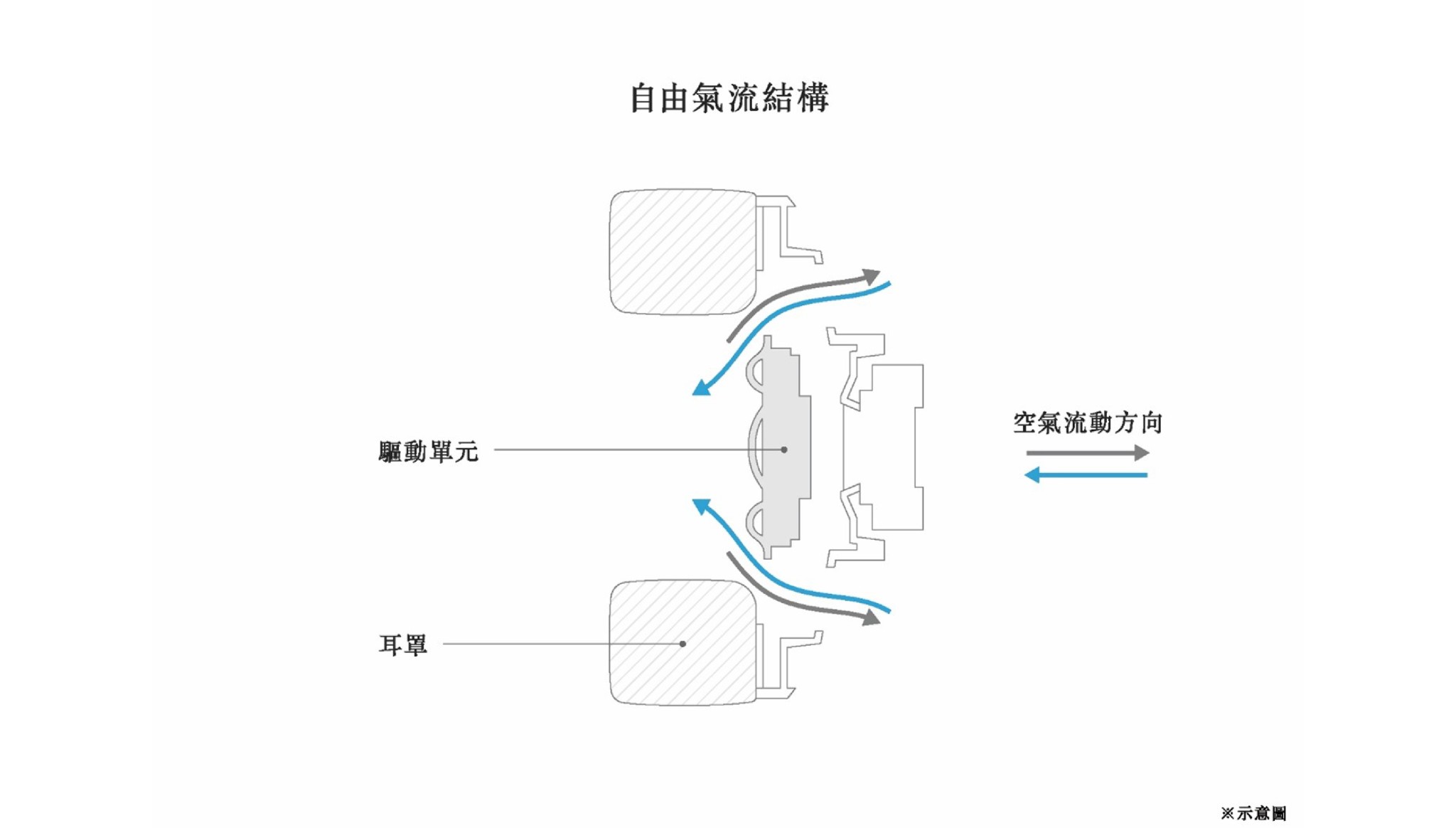

Most headphones generate deep bass response by accumulating air pressure within a sealed enclosure between the diaphragm and the listener’s ear. While this design enhances low-frequency impact, it can sound overly colored or unnatural, especially to those accustomed to the open, unconfined presentation of two-channel loudspeakers.

With the DX6000, final takes a fundamentally different approach.

Thanks to an innovative dynamic driver design featuring an exceptionally low resonant frequency (f₀), the driver itself naturally produces rich, powerful bass—without relying on sealed chambers or artificial reinforcement.

final reimagines the open-back concept through what it calls the Free Airflow Architecture. The DX6000’s housing is precisely machined from an aluminum-magnesium alloy, and features an internally connected front-and-rear acoustic chamber system that optimizes airflow within the earcup. This design allows air to move freely and naturally, minimizing acoustic pressure buildup and delivering a vastly more open and uncolored sound.

Paired with breathable, paper-fiber ear pads and headband materials, the DX6000 creates what final describes as an "ultra-open soundstage"—a spatial presentation that exceeds the capabilities of conventional open-back headphones.

In practice, the experience resembles listening in a miniature concert hall built into the earcups. Instruments feel liberated from the physical boundaries of the enclosure, forming a three-dimensional sound field akin to near-field bookshelf speakers. It’s a design particularly well-suited to classical music, live recordings, and any genre that demands natural depth and spatial realism.

The DX6000 features a chassis meticulously carved from a single block of aluminum-magnesium alloy. This high-precision machining process results in an exceptionally rigid and stable structure, providing a solid foundation for the dynamic driver unit.

By minimizing unwanted vibration and structural resonance, the housing plays a critical role in preserving sonic purity, reducing distortion, and ensuring that every nuance of the music is delivered with clarity and integrity.

This is not just industrial design—it's acoustic architecture, engineered to let the driver perform at its absolute peak.

To complement the DX6000’s extraordinary acoustic performance, final has developed a bespoke set of ear pads—engineered for both sonic transparency and lasting comfort.

At the core is a highly breathable foam, chosen for its ability to maintain air circulation while preserving acoustic integrity. The outer layer is wrapped in a specially selected Washi fabric—a traditional Japanese paper-based textile known for its dry, silky texture, exceptional durability, and natural moisture resistance.

This same premium material is also used on the headband, offering a consistent tactile experience across all contact points. Beyond its comfort and resilience, Washi contributes to the DX6000’s signature open sound by minimizing reflective surfaces around the ear.

The result is a wearing experience that feels light, cool, and natural, even during extended listening sessions—combining the art of traditional Japanese materials with the precision of modern acoustic design.

Product Specifications

Driver

Magnesium Alloy Dynamic Driver

Cable

OFC Cable

Sensitivity

83dB/mW

Impedance

47 Ω(1k Hz)

Welcome to leave your comments for other users' reference