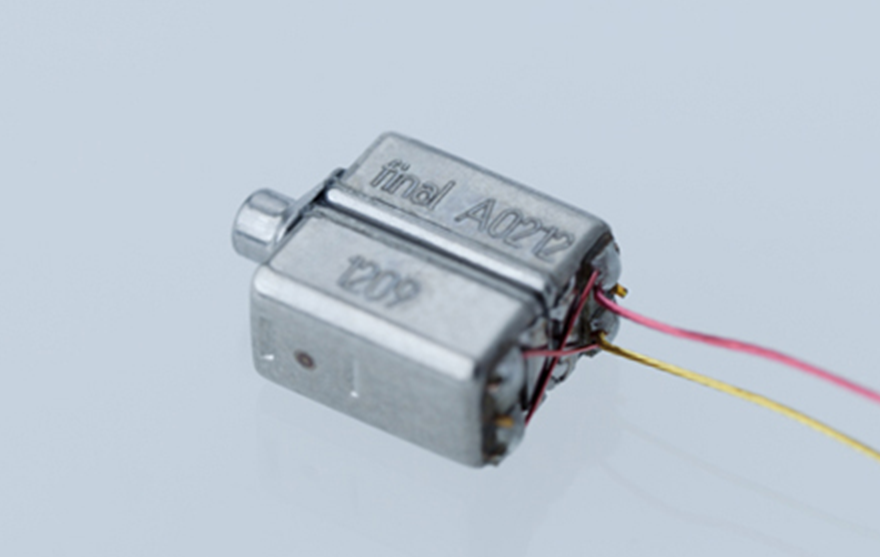

Full Range Dual Balanced Armature Driver

Dual use of final audio design’s original full-range balanced armature driver unit. By doing so, we’ve realized a weighty bass tone.

Balancing Air Movement

Final developed a technology that reproduces bass tones with a three-dimensional feel using in principle problem-free single driver unit full range reproduction. The performance of the balanced armature type was re-examined and the airflow inside the housing was also focused on. An aperture in the usually sealed driver was created and a mechanism named BAM ( Balancing Air Movement) was developed to regulate the airflow inside the housing.

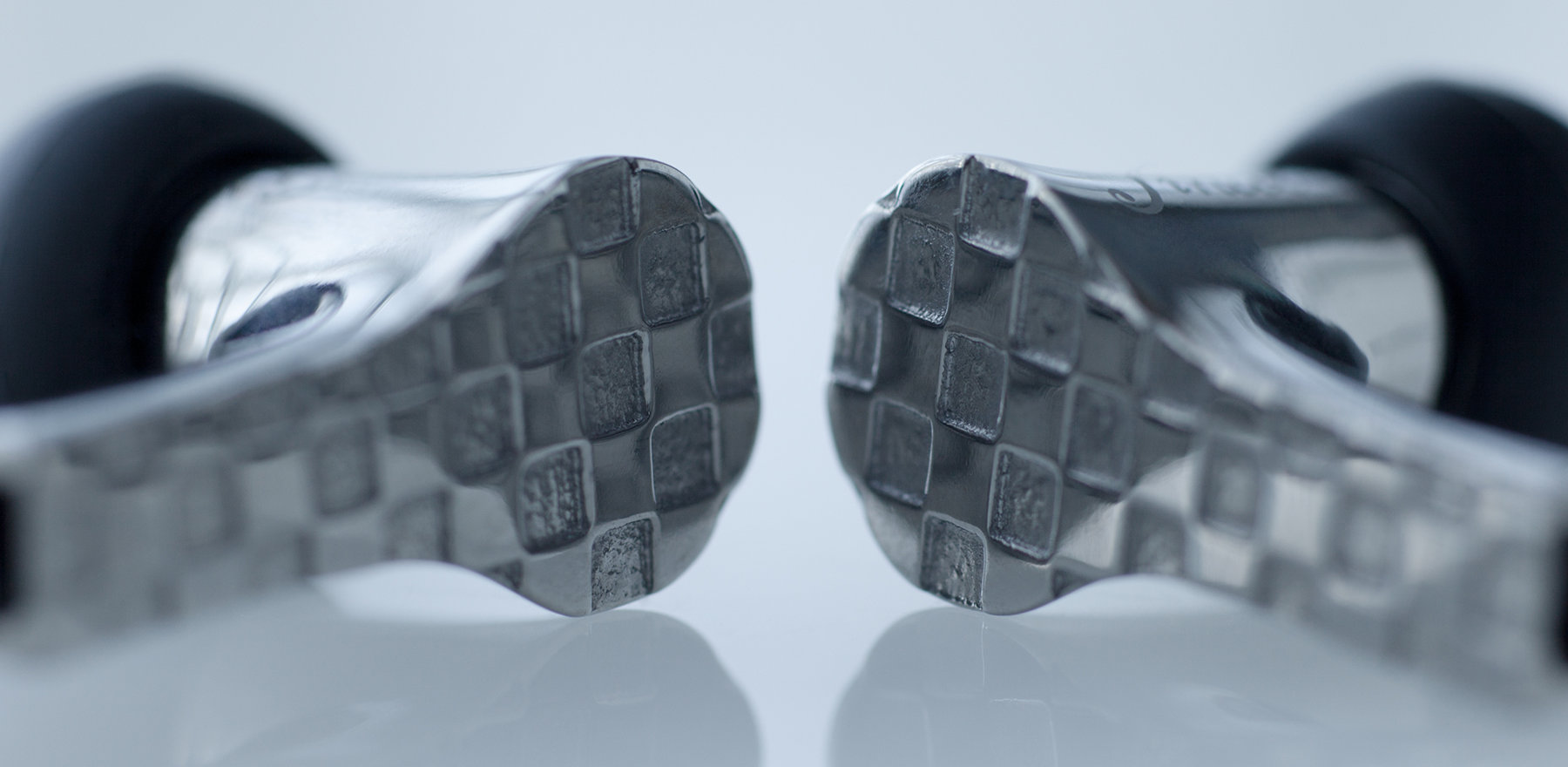

Titanium 64 housing formed via 3D printer

Shapes formed using a 3D printer don’t just appear with the touch of a button.

Different knowhow is especially necessary at each point when it comes to forms created from metal. Each point is quantified and accumulated as explicit knowledge. But when it comes to deciding how to go about combining all of this different knowhow and in what order of precedence, then what is necessary is the intuition of the craftsman. Rather than rendering the work of the craftsman unnecessary, shaping metal using a 3D printer necessitates there being human resources that could be termed digital craftsmen, in that they consider the output data to be created that takes into account the shape of the finished product, the cost, precision, the smoothness of the surface and a number of other elements. To reach the best output data for the housing here, we trialed a great number of prototypes.

And finishing off the surface is not easy either. The 3D printer irradiates metal powder over an extremely small area with a laser, melting it and then hardening it over and over so that the form is created. Owing to this, the surface is pocked with the marks left by the laser’s irradiation and has a rough finish. Polishing this up requires just as much knowhow as shaping the object does. It was thought that polishing it to the degree that its precision as a product was maintained was impossible. Here, with the cooperation of a coordinator specializing in specially-processed metals, we combined the skills of the craftsmen in many ways and with the output from the 3D printer, realized a beautifully polished finish for the titanium 64 (usually a hard metal to polish) housing.

Stainless mesh filter + acoustic resistor

We’ve achieved a balance between medium and high tones with stainless steel mesh and acoustic resistor.

Specifications

Housing

Titanium Alloy

Driver Unit

Dual Balanced Armature Full Range Driver

S.P.L

112dB

Impedance

8 Ohms

Length of Cable

1.2m

Weight

Approx. 26g

Welcome to leave your comments for other users' reference