D.U.C.C stands for Dia Ultra Crystallized Copper which is specifically developed copper wire for high-end audio cables. D.U.C.C has controlled crystal structure and the minimized transmission loss.

Patent technology and registered trade mark of Mitsubishi Materials LTD.

A film made by stacking a magnetic foil that achieves high electromagnetic wave absorption performance, which is equally effective in reducing radiated noise and improving resistance to external noise. Developed by NTT Advanced Technology Corporation.

Stress-free processing of raw materials is another remarkable feature along with the use of 6N raw material, and the mainstay technology of ACROLINK brand products.

Although the raw materials have improved purity, enlarged crystals and extremely stable atomic arrangement external stress cannot be avoided at many stages of processing due to bending, etc. Disorder in the atomic arrangement called a “deformation defect” may occur during the process. The raw material is generally annealed to accelerate crystalline growth to restore the original large crystalline structure during the wire drawing process, but when the finished wire is being wound on reels for distribution or being wired, a problem arises due to some external stresses loaded on wire.

The ACROLINK's stress-free products are the only cables in the world which, through a unique annealing process, have high purity copper characteristics with a crystalline structure that is restored to its original stable crystalline structure through a self-annealing phenomenon, except when the external stress is extremely severe. Transformation of atomic arrangement occurs when the wire heated after the wire drawing process is reduced to only one billionth of that of 4N copper and the number of crystals is also reduced to 1/80 to 1/100. Loading wire with electric current accelerates aging or self-annealing function, and reduces residual deformation to restore the original stable crystalline structure making the wire able to transmit wide-range frequencies with ultrahigh fidelity.

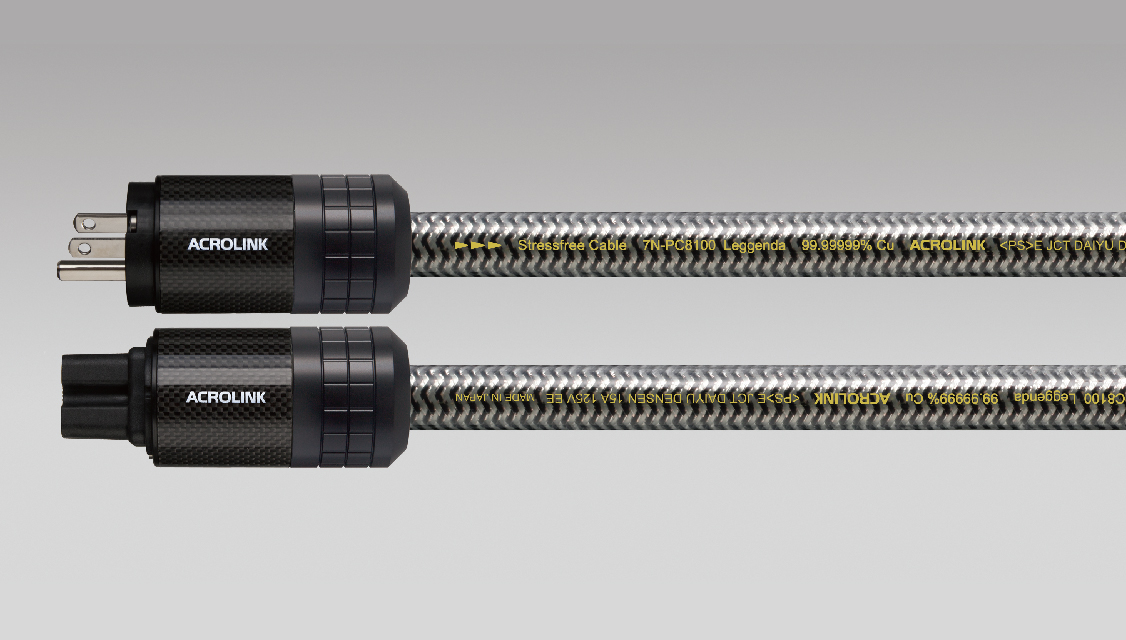

Specifications

Conductor

7N Cu D.U.C.C Stressfree 0.37Φ x 50 strands x 2 cores(AWG 10)

4N5 Cu for ground 0.37Φ x 50 strands(AWG 10)

Insulation material

High molecular Polyolefin Resin (Black & White & Green)

1st Inner sleeve

High molecular Polyolefin + tungsten + amorphous + carbon powder

2nd Inner sleeve

Polyolefin with Resonance control powder

Shielding

Polyurethane enameled wire(Black) + Silver plated copper(Silver) braided wire

Outer sleeve

UV resistant Polyurethane

Conductor resistance

3.3mΩ/m

Cable diameter

16.0mm

Power plug & IEC connector

Contact parts

Beryllium copper

Plating

Silver layered rhodium(Polished before plating)

Body

Special resin + brass + carbon fiber + aluminum

Black anodized aluminum specially for 7N-PC8100 Leggenda

Welcome to leave your comments for other users' reference